The automotive sector has consistently pushed the limits of engineering and design, making it a hub for innovation. Precision manufacturing is more important than ever as cars get more complicated and prioritize efficiency, safety, and cutting-edge technology. The cutting edge of this development is Wire Electrical Discharge Machining (Wire EDM), an unconventional machining technique that is subtly changing the production of intricate automotive parts.

The Precision Advantage: From Production to Prototypes

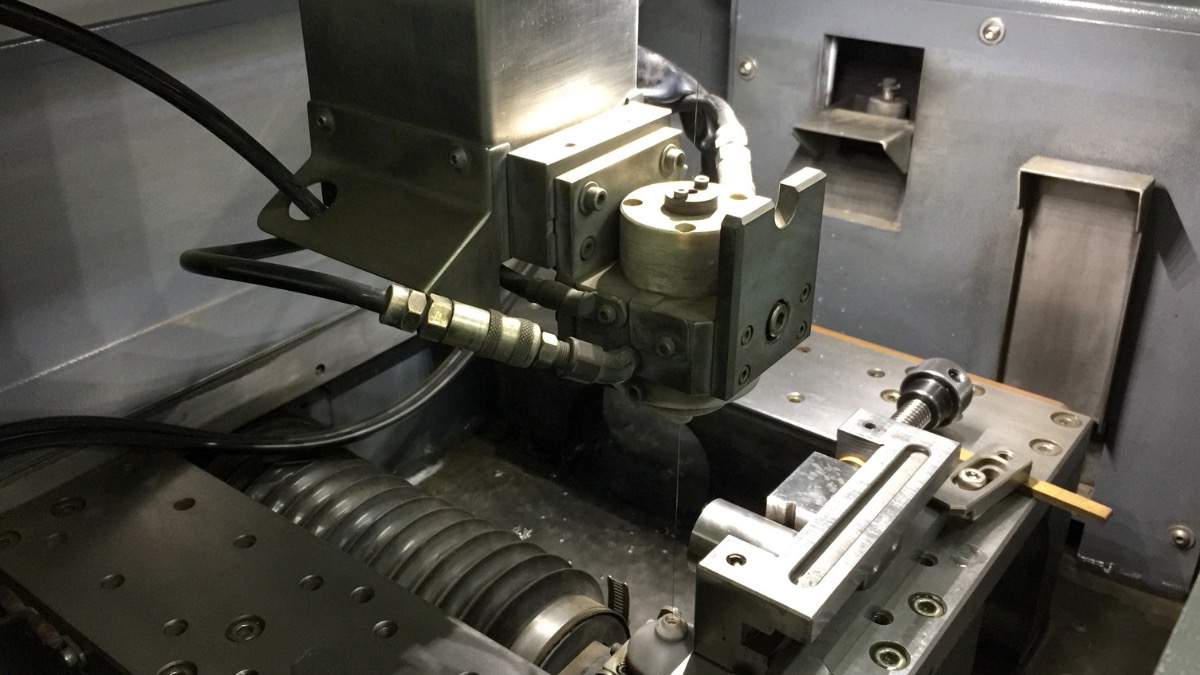

The accuracy of Wire EDM is revolutionary in a field where tolerances are expressed in microns. Wire EDM uses a thin, electrically charged wire to cut through conductive materials with remarkable accuracy, in contrast to traditional machining, which uses cutting tools. The physical force and heat involved in conventional machining are removed by this method, which can lead to material stress or distortion.

This results in a number of significant advantages for the automotive sector:

- Complex Geometries: Unlike traditional techniques, wire EDM can produce complex internal features, sharp corners, and intricate shapes. This is crucial for parts like engine valves, transmission parts, and fuel injector nozzles.

- Fast prototyping: is essential as the automotive industry transitions to electric and driverless vehicles. The development cycle can be significantly shortened by engineers using wire EDM to swiftly create high-precision prototypes of new designs.

- Hard Material Machining: For durability, automotive parts frequently need to be made of exotic alloys and hardened steels. Wire EDM is perfect for everything from high-performance engine parts to stamping die tooling because it can easily cut these materials without sacrificing their integrity.

Give Axsys Industrial Solutions a call at (248) 926-8810 for knowledgeable guidance and state-of-the-art Wire EDM solutions for your automotive applications.

Important Uses in Contemporary Automobiles

Because of its adaptability, wire EDM is essential in many areas of the automotive manufacturing industry.

- Fuel Systems: Engine performance and efficiency depend heavily on the accuracy of fuel injector components. These parts are made with the precise tolerances needed for the best fuel atomization using wire EDM.

- Transmission and Drivetrain: To guarantee smooth operation and longevity, modern transmissions’ complex gears, splines, and internal components require a high level of precision. These parts can be produced with unmatched accuracy using wire EDM.

- Dies and Molds: Stamping dies and injection molds are frequently used in the production of automotive parts, ranging from body panels to plastic components. The preferred technique for making these tools is wire EDM because it can create incredibly intricate and robust shapes. This guarantees that each and every component made from the die or mold is identical and satisfies exacting quality requirements.

- Sensor and Electronic Components: Sensor technology is booming as a result of the development of autonomous vehicles. For sensors and other electronic systems, where even the smallest error can impair functionality, wire EDM is utilized to produce precise parts.

Did You Know?

That Wire EDM can cut materials that have already been heat-treated and hardened? This saves a lot of time and money by removing the need for a separate heat-treatment procedure after machining.

As the automotive industry continues to evolve, the demand for precision, efficiency, and high-quality components will only grow. Wire EDM is not just a manufacturing process; it’s a key enabler of this progress. For expert advice and cutting-edge Wire EDM solutions for your automotive applications, call Axsys Industrial Solutions at (248) 926-8810.

Frequently Asked Questions

Is wire EDM limited to metal components?

Since Wire EDM depends on electrical conductivity, it can only be applied to materials that are electrically conductive, like titanium, steel, aluminum, and different alloys. Unless they have a conductive coating, it is not appropriate for ceramics or plastics.

What distinguishes Wire EDM from conventional CNC machining?

By using a physical cutting tool, CNC machining can distort the workpiece by producing pressure and heat. Wire EDM, using a thin wire and electrical sparks, vaporizes material without stress, ideal for complex shapes, hard materials, and burr-free finishes.