Tool and Die Maker Speeds Expansion Using Mastercam

With short lead times and high demand for their services, Triple C Machine pushes its CNC machines to optimum speeds by programming toolpaths with Mastercam. By utilizing the entire flute length of cutting tools, air cutting is minimized or eliminated, saving wear and tear on tools and ensuring constant chip load.

Quick Facts:

Product Used: Mill, Lathe

Indsutry: Transportation, Consumer Goods, Job Shop, Energy, Tool & Die

Project Details:

- The Challenge: Producing a variety of complex parts while maintaining short lead times and balancing a constant, full workload.

- The Solution: Mastercam, the most widely used CNC software for CAD/CAM operations.

- The Benefits:

- Dynamic Motion technology optimizes machine performance, minimizing air cuts, reducing machine wear, and ensuring constant chip load.

- OptiRough toolpath removes large amounts of material, creating a fully roughed part made in much less time than could be done using traditional roughing methods.

- Solids feature allows designers to turn customer CAD drawings into solid model files, saving programming time.

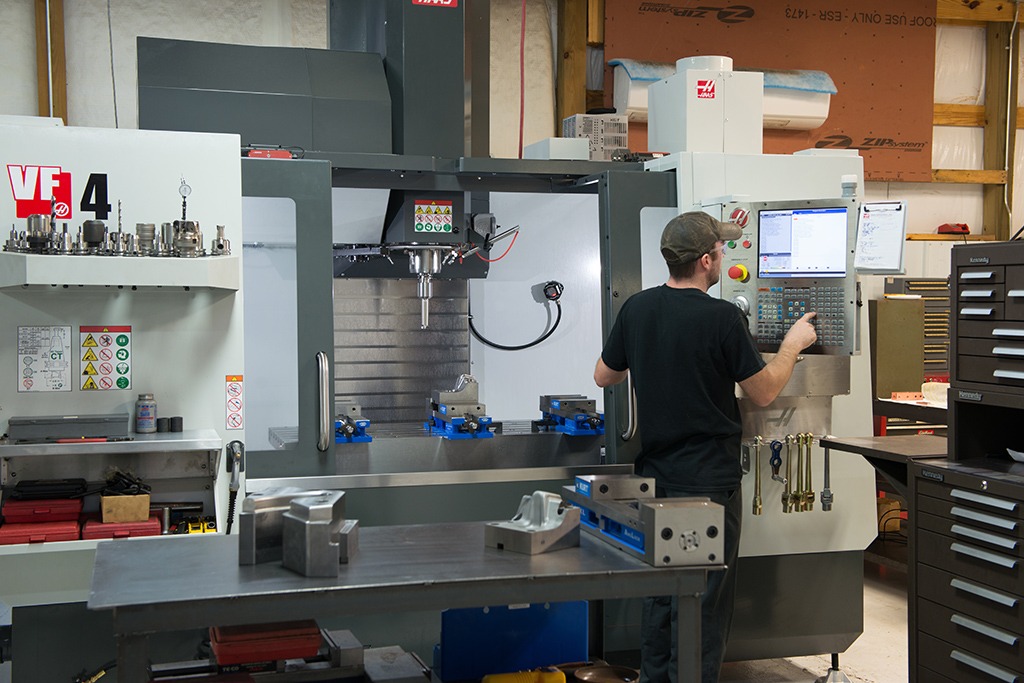

After nine years as a plant manager for a tool and die maker, Jason Cantrell established Triple C Machine in Livingston, Tennessee. This machine shop specializes in tool and die design, building, and repair, as well as production machining, metal stamping, and fabrication. CNC milling machines, lathes, and wire EDMs are used to machine A2, D2, DC53, and 4140 steel to serve the automotive, appliance, environmental, and special machine industries.

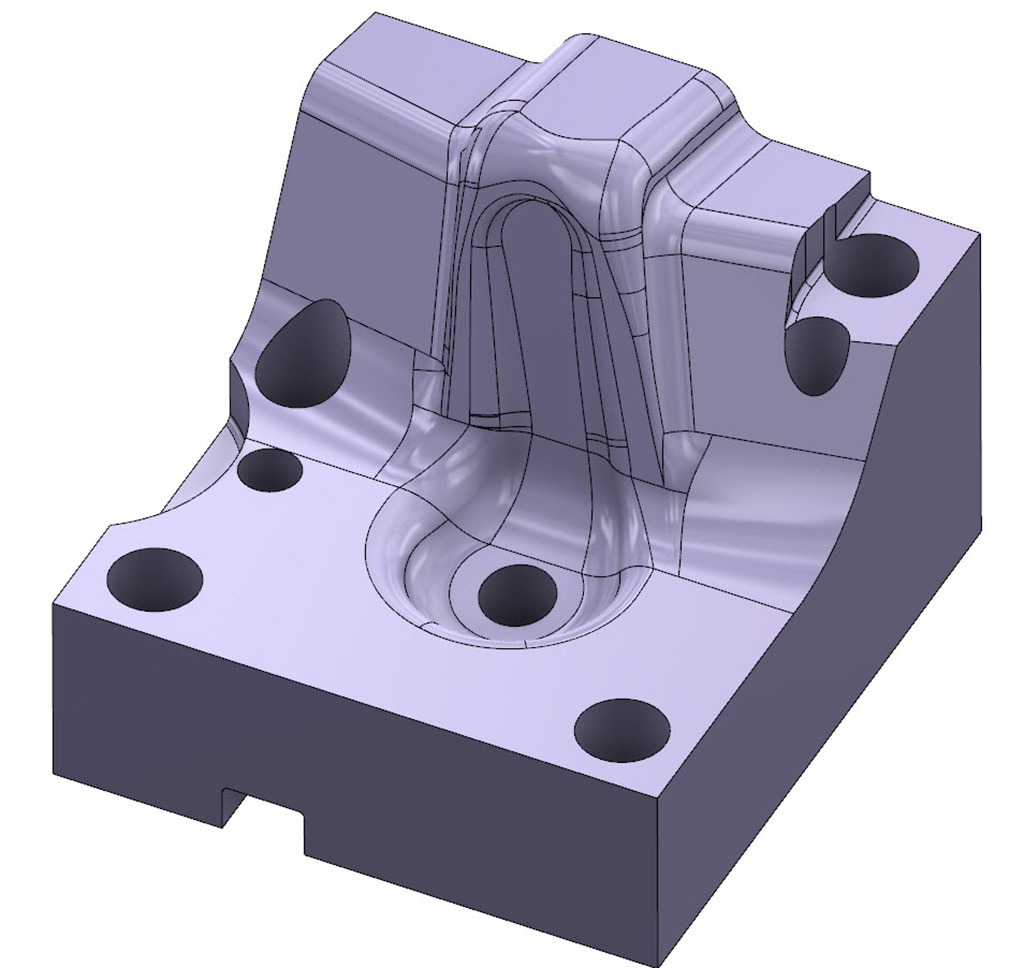

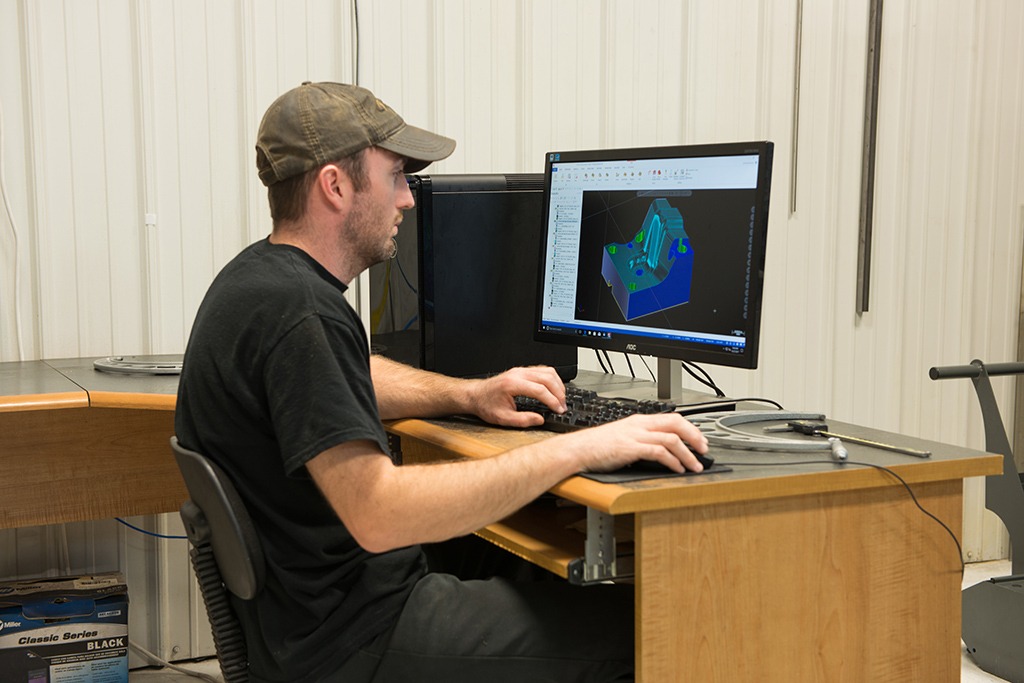

The prospect of 3D work led the manufacturer to investigate CAD/CAM software options. “When you get into 3D machining, you find out quickly that software is a really important part of the equipment,” said Cantrell, Triple C president and owner. “We had to go with Mastercam. We do a lot of 3D machining, a lot of hard milling. It has really worked well for us.”

In addition to production machine work, Triple C designs and manufactures a little bit of everything. “Most of our parts are for die/stamping,” said Josh Key, Triple C Machine CNC programmer. “We make details and sections for these dies for local facilities. That’s where we use Mastercam the most.”

With short lead times and a steady workload, Triple C pushes its CNC machines to optimum speeds by programming toolpaths with the software’s Dynamic Motion technology for high speed milling. By utilizing the entire flute length of cutting tools, air cutting is minimized or eliminated, saving wear and tear on toolstools, and ensuring constant chip loading.

“We use a lot of high feed cutters and the OptiRough toolpath to get our parts roughed out,” said Key. “The toolpaths keep our tools in constant motion with chips flying. There’s not a lot of air cutting, no wasted time. They really keep our cutting tools engaged.”

Triple C does not regularly machine large part runs; in one day, one operator may produce five parts, all completely different.

“We’re a job shop and everything we do is different,” said Key. “With the software, I know that I can get more out of my tools—longer tool life and faster cycle times. I have less chatter and better finishes.”

For Triple C customers who do not submit solid models of parts, designers use the Solids feature to design and turn customer CAD drawings into solid model Mastercam files. Designers and programmers can mix and match several modeling techniques, adding surface or wireframe elements to the model, cutting down on programming time.

“Sometimes stamping customers will provide 3D models of what they need,” said Cantrell. “We take their models and make our machining programs from them. The software has helped us with this, because before, we could never get the surface finish tolerances close enough. We had to spend a lot of time polishing. Now we can finish the part on the mill.”

To check for gouges and ensure proper tool engagement, Triple C runs Mastercam Machine Simulation on 3D parts. Once simulation is complete and the process is verified, operators load the part and program and start the cutting process.

“The simulation program has really helped us,” said Key. “If the machine is going to run for three or four hours by itself, we can verify the process on the computer. The operator does not have to watch over it.”

Triple C started with one but now has several seats of Mastercam, which are especially helpful when a customer breaks a die or a part.

“We’ve got the capacity for each of us to be working on a different piece of the puzzle, or for a different customer,” said Key. “We don’t have a lot of lead time here. Everything has to be flipped quickly, so having multiple guys programming lets us take on more work.”

With the continued help of Mastercam’s high-speed toolpaths, simulation, and process control capabilities, Triple C will be able to take on those jobs and then some. “Our line of work is so competitive,” said Cantrell. “We have new machines, new software, and great people. As long as we maintain that, I think we’ll stay busy.”