While building a CMM path Plan, you can easily add screenshots that will be included in the inspection report, providing great detail of measurement results. The user may pre-select the features for the screenshot, and if no features are selected, all Plan features appear in the screenshot.

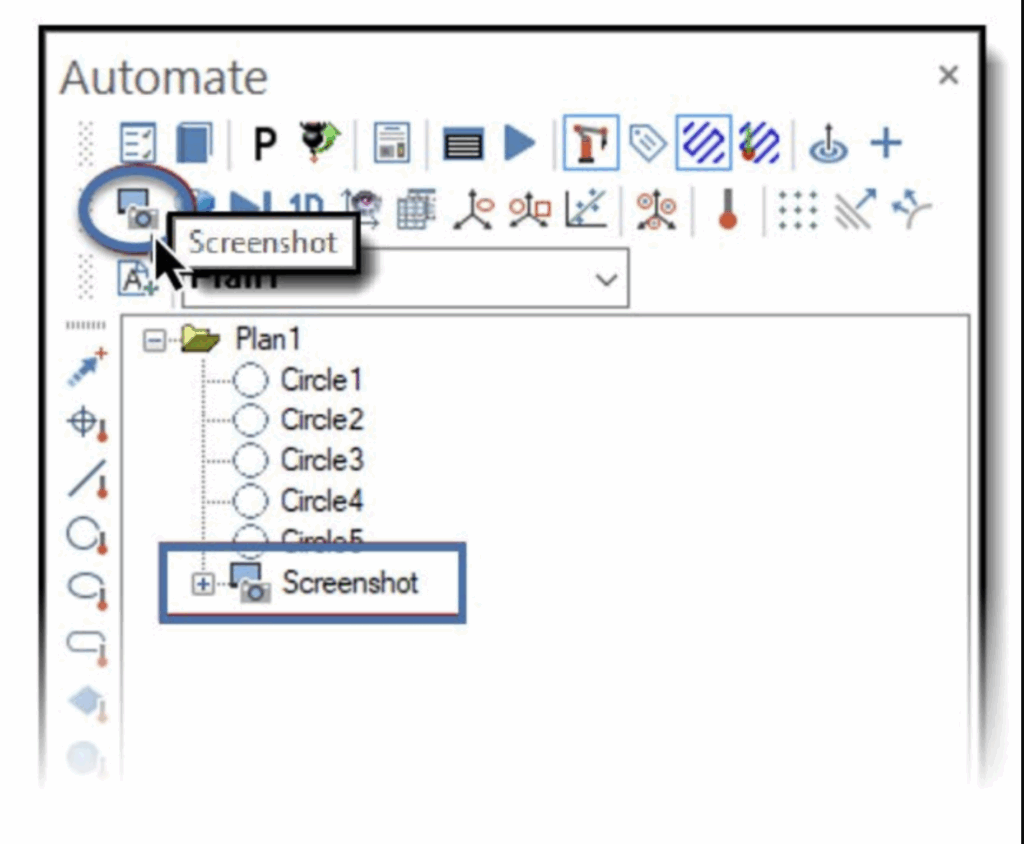

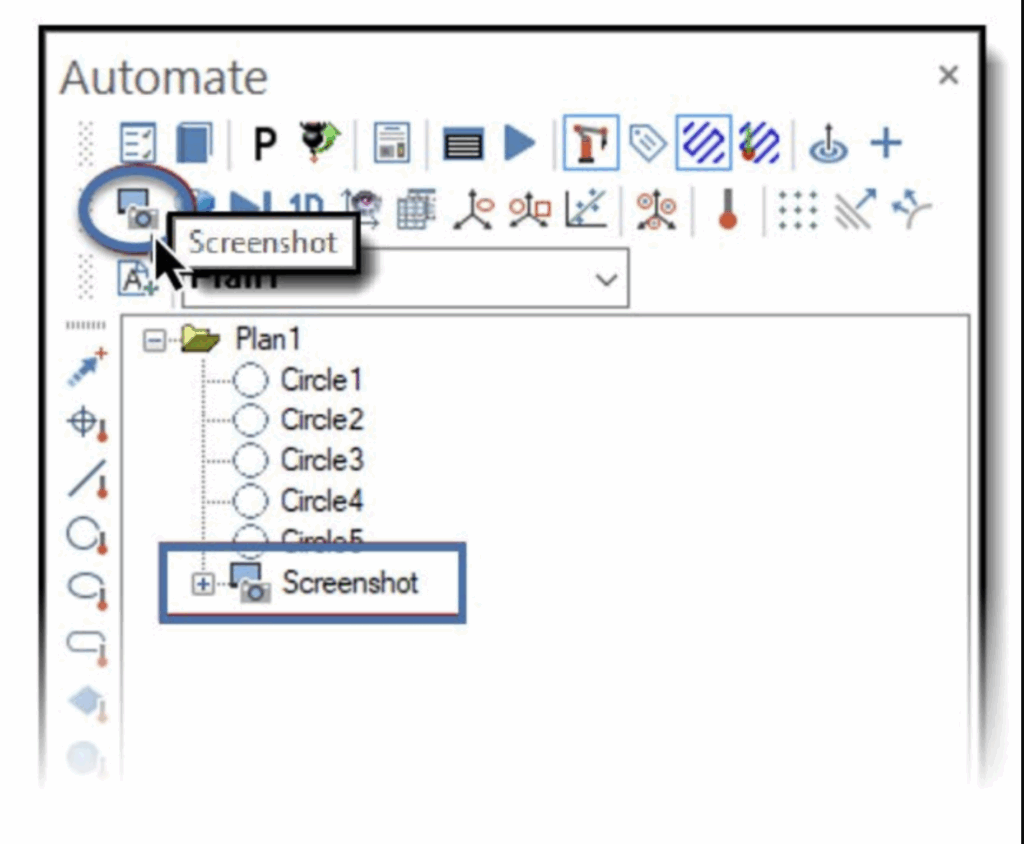

1.) Select the Screenshot tool button from the Automate Toolbar.

2.) The Graphics window appears in white; click in the window, manipulate the View to the desired screenshot view, and press Enter.

3.) The screenshot view is saved and appended to the end of the Plan.

Screenshots and Views can be edited by double-clicking them in the AUTOMATE Manager and editing in the Report Manager which pops up for the user to make changes.

Learn more.

https://cutt.ly/MASTERCAMBLOG_CMM

Overview of CMM Programming Software

CMM programming software is essential for automating the inspection process in manufacturing. It enables users to efficiently create measurement paths for Coordinate Measuring Machines, ensuring high accuracy and consistency in quality control.

This software typically features intuitive interfaces and robust tools for designing measurement routines. Users can leverage advanced capabilities such as real-time data visualization and customizable reporting options, which facilitate thorough inspections and enhance productivity on the shop floor.

Key Features of Axsys CMM Software

Axsys CMM programming software offers a suite of powerful features designed to streamline the measurement process. Key functionalities include automated path generation, user-friendly graphical interfaces, and the ability to integrate with various measuring devices.

Additionally, the software supports extensive customization options, allowing users to tailor measurement plans to specific project requirements. Features such as live feedback during measurement and detailed reporting tools contribute to improved accuracy and efficiency in quality assurance workflows.

Benefits of Using CMM Programming in Manufacturing

Implementing CMM programming in manufacturing processes provides numerous advantages, including enhanced measurement accuracy and reduced inspection times. By automating the measurement process, manufacturers can minimize human error and ensure consistent quality across products.

Furthermore, the integration of CMM programming software into production workflows enables better resource management and cost savings. Companies can achieve faster turnaround times and improved compliance with industry standards, ultimately leading to greater customer satisfaction and competitiveness in the market.

Step-by-Step Guide to Creating Inspection Reports

Creating comprehensive inspection reports is made simple with Axsys CMM programming software. Users can easily generate reports by selecting the desired measurement paths and including relevant screenshots to provide visual context for the results.

This step-by-step guide walks users through the process of documenting their measurement results effectively. By utilizing the software's built-in tools, users can ensure that their reports are detailed, accurate, and tailored to meet specific industry requirements, enhancing their overall reporting efficiency.