- Customer Care | Need help? Call us: (855) 687 7941

- Customer Care | Need help? Call us: (248) 926 8810

Menu Close

- Home

- PRODUCTS & SERVICES

Company

The Axsys Advantage

Financing & Promotions

Mastercam Solutions

Specialty Solutions

Mastercam Add-On Products

In Action

- RESOURCES

- Training

- Blog

- Contact Us

- Home

- PRODUCTS & SERVICES

Company

The Axsys Advantage

Financing & Promotions

Mastercam Solutions

Specialty Solutions

Mastercam Add-On Products

In Action

- RESOURCES

- Training

- Blog

- Contact Us

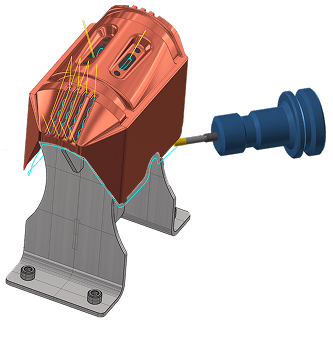

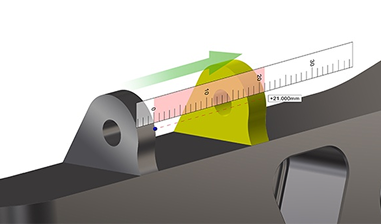

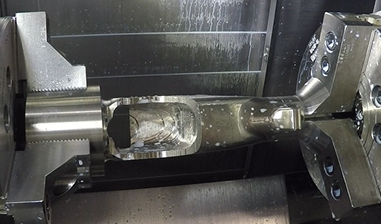

Mill

Mill

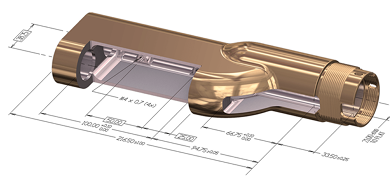

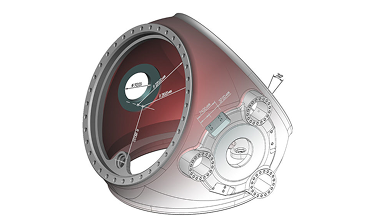

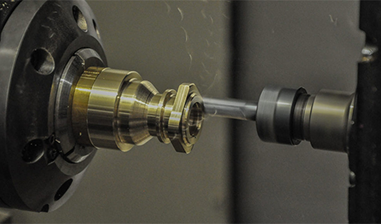

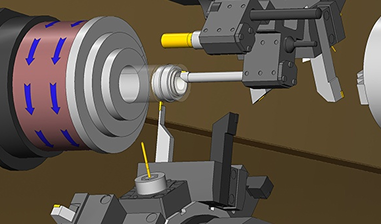

Lathe

Lathe

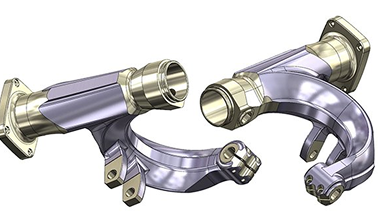

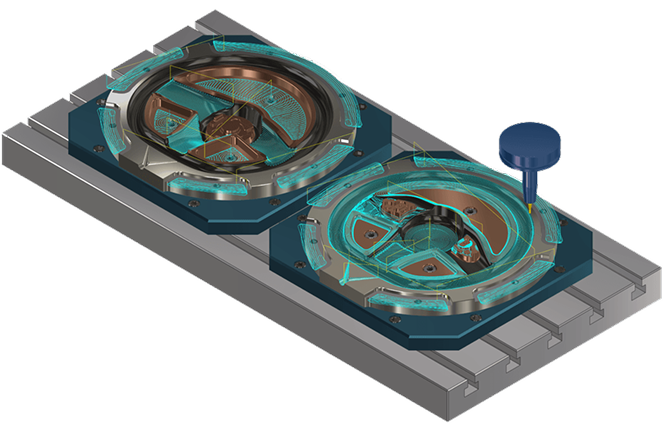

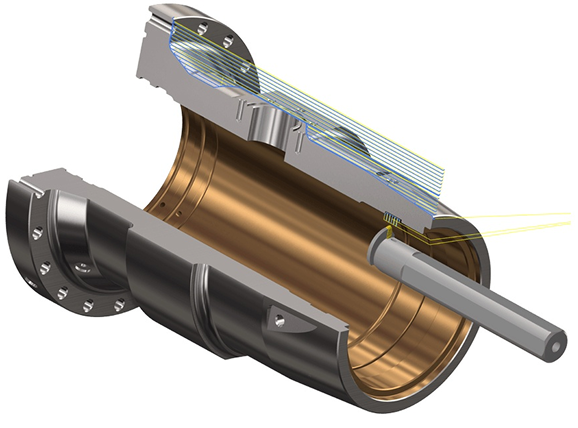

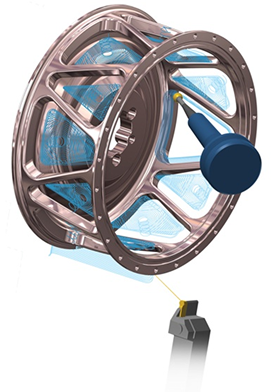

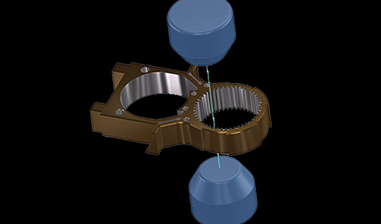

Mill-Turn

Mill-Turn

Wire EDM

Wire EDM

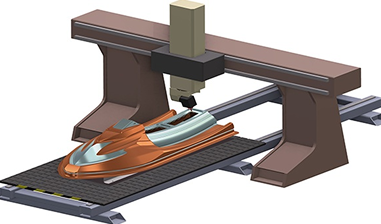

Router

Router