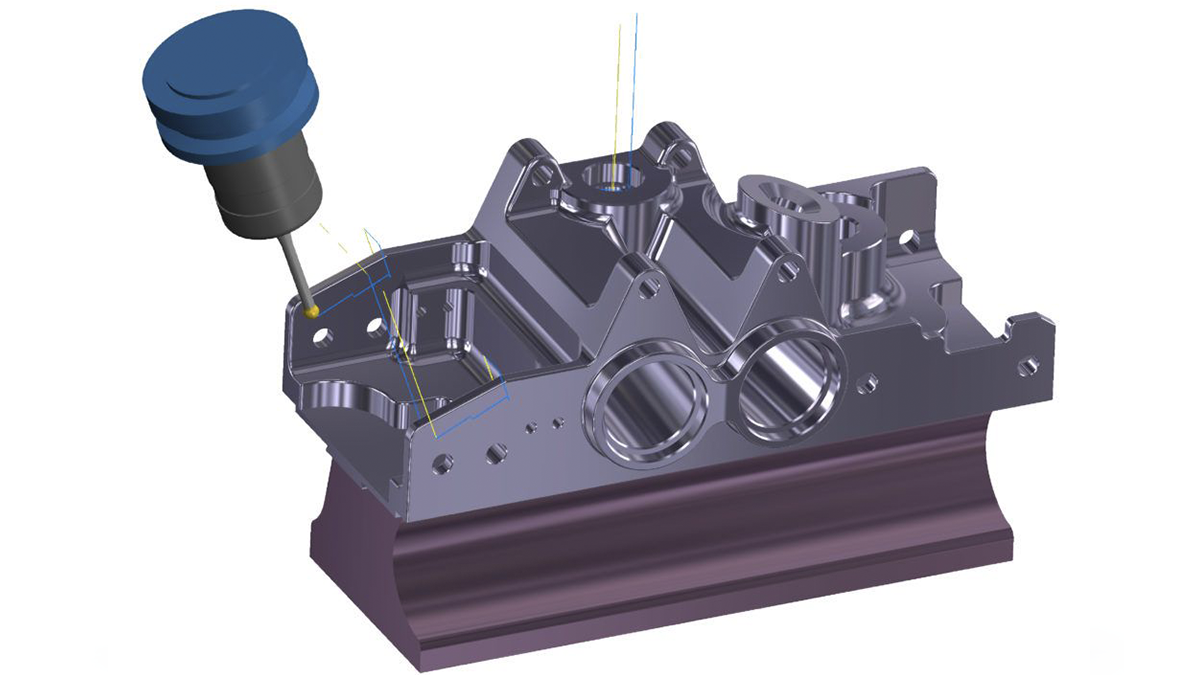

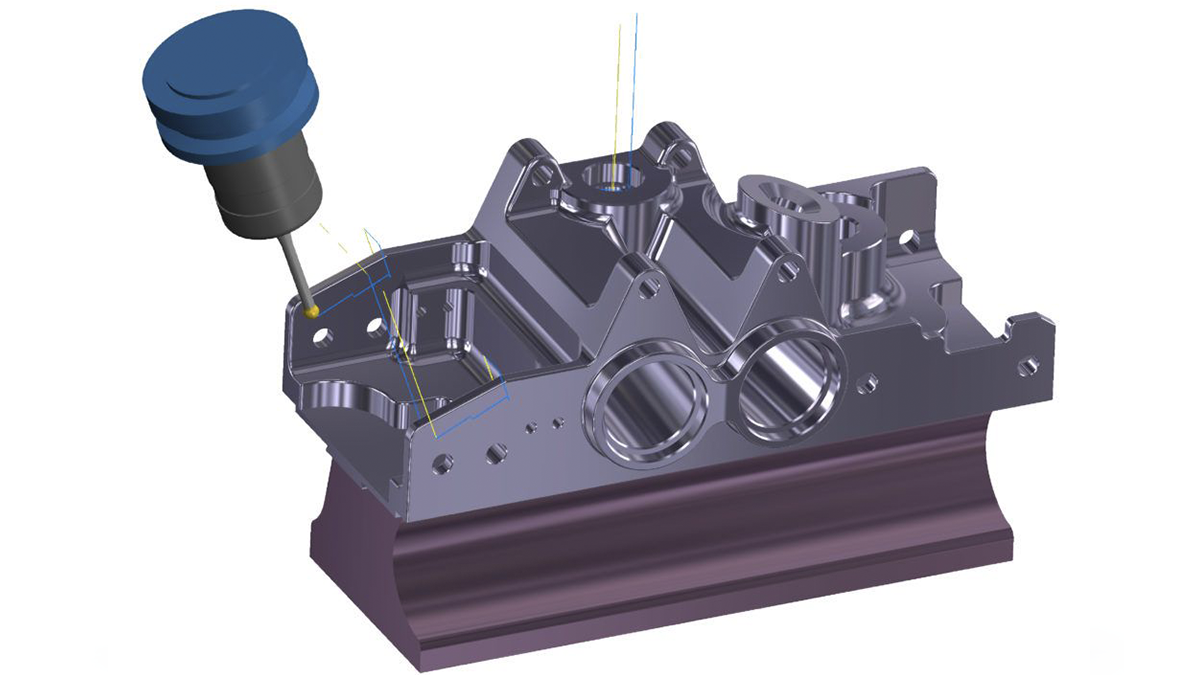

Productivity+ TM gives you the ability to use a Renishaw measuring probe on a machine tool to update fixture offsets, tooling offsets, program orientation, and report on critical dimensions and tolerances. It also assists in lights-out manufacturing and running a machine tool without an operator.

Productivity+ provides an easy-to-use platform for incorporating simple measurement functionality and more advanced in-process intelligence into machining programs. It can simplify a wide range of measurement and process control tasks, such as component set-up, verification of critical features, and process development.

Read more.

https://cutt.ly/MASTERCAMBLOG_PRODUCTIVITY

Key Features of Productivity+

Mastercam's Productivity+ offers a suite of features designed to enhance measurement and process control in manufacturing environments. By integrating seamlessly with Renishaw measuring probes, it enables users to effortlessly update fixture and tooling offsets, ensuring precision in machining operations.

Additionally, the software simplifies complex tasks such as component set-up and verification of critical features. This capability not only streamlines workflows but also significantly reduces the potential for errors, ultimately leading to improved product quality and operational efficiency.

Benefits of Using Renishaw Probes with Productivity+

Integrating Renishaw measuring probes with Productivity+ brings numerous advantages to manufacturing processes. This combination allows for real-time data collection, making it easier to adjust machine settings on-the-fly and maintain high levels of accuracy throughout production runs.

Moreover, the use of these probes enhances operator-less operation and lights-out manufacturing capabilities. By automating measurement tasks, businesses can achieve greater productivity and reduce labor costs, paving the way for more efficient manufacturing practices.

Applications of Productivity+ in Modern Manufacturing

Productivity+ is versatile and can be utilized across various sectors within the manufacturing industry. Whether it's in aerospace, automotive, or general machining, the software's ability to manage complex part designs and facilitate precise inspections makes it an invaluable tool for manufacturers.

For instance, companies can leverage Productivity+ for process development and optimization, ensuring that their production methods remain cutting-edge and competitive. This adaptability to different applications showcases the software's capability to meet diverse manufacturing needs.

Getting Started with Productivity+

To begin using Productivity+, users can easily access the software through Axsys Incorporated's online platform. The installation process is straightforward, and comprehensive resources are available to guide new users through setup and initial configuration.

Furthermore, Axsys offers training sessions and customer support to assist users in maximizing the benefits of Productivity+. By investing time in learning the software, manufacturers can quickly realize significant improvements in their operational efficiency and accuracy.