Multiaxis machining is often seen as something only big players in industries like aerospace can handle. However, there are several myths surrounding it that we’re here to debunk.

Myth #1: You need a multiaxis machine to start multiaxis machining. Not true! With 3+2 machining, you can use a traditional 3-axis milling center. This approach provides many benefits of multiaxis machining without needing a specialized machine. Mastercam Mill offers solutions for 3+2 machining.

Myth #2: Multiaxis is only for aerospace parts. In reality, almost any shop can benefit from multiaxis. It reduces setup times, which is crucial in today’s job market where skilled machinists are scarce. Multiaxis machining can streamline operations, making your shop more efficient and competitive.

Myth #3: Multiaxis is too complicated to be profitable. While it may seem intimidating, learning multiaxis isn’t as complex as it seems. Mastercam’s multiaxis toolpaths are intuitive, and your local reseller can provide training and support to help you get started. Resources like Mastercam University, camInstructor, and Streamingteacher are also available for additional learning. Don’t let fear hold you back from exploring the benefits of multiaxis machining for your shop.

Read now.

https://cutt.ly/MASTERCAMBLOG_MYTHS

Understanding Multiaxis Machining

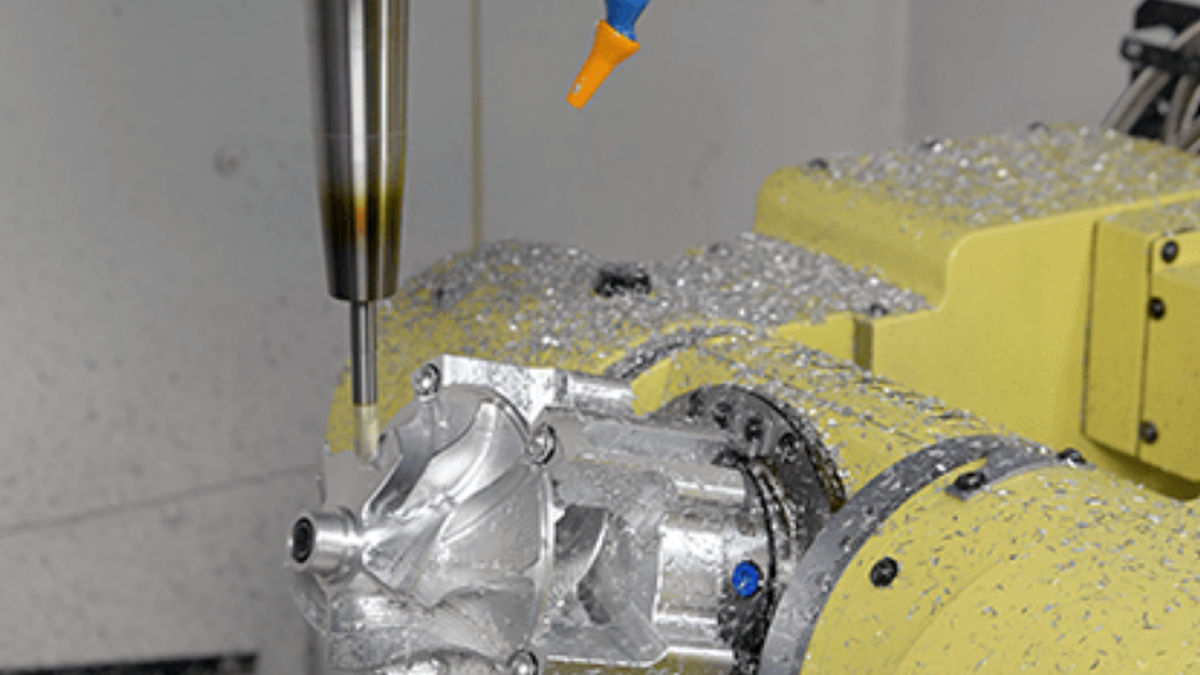

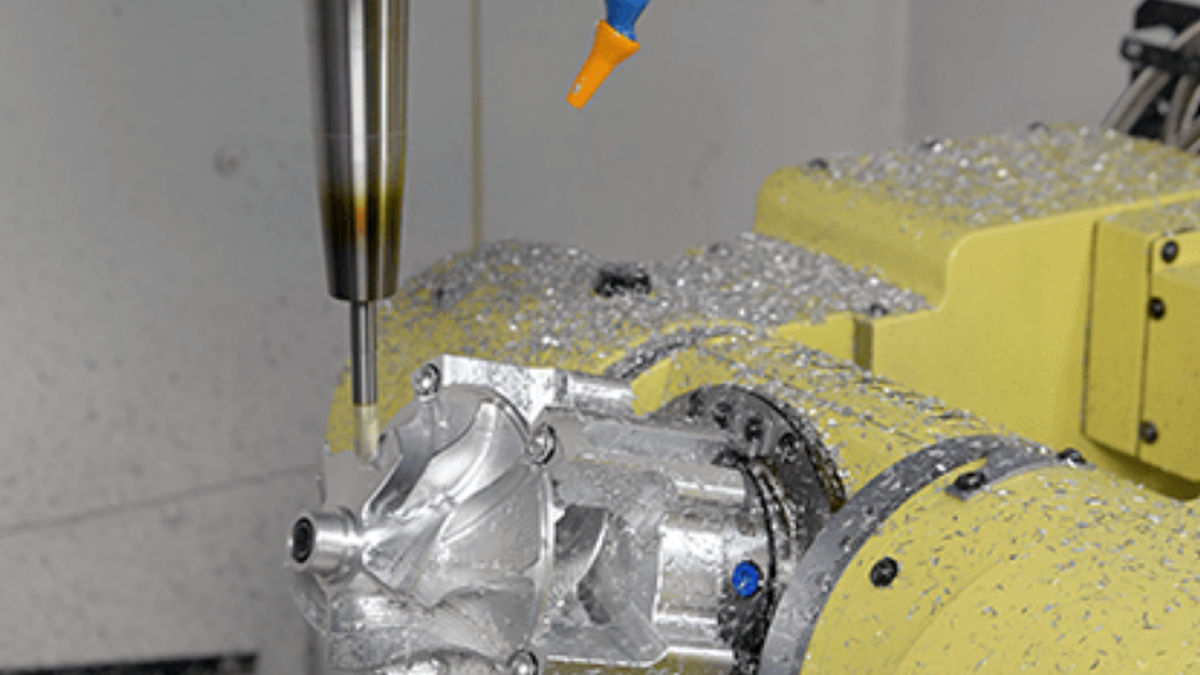

Multiaxis machining refers to the ability of a machine tool to move in multiple directions simultaneously, allowing for the creation of complex geometries that would be difficult or impossible to achieve with traditional 3-axis machining. This capability is essential for industries that require high precision and intricate designs.

This technology is not limited to advanced aerospace applications; it is increasingly accessible to various sectors, including automotive, medical, and consumer goods. By utilizing multiaxis machining, manufacturers can streamline production processes, reduce material waste, and improve overall part quality.

Benefits of Multiaxis Machining for Small Businesses

Small businesses can significantly benefit from adopting multiaxis machining techniques, as these methods enhance productivity and reduce turnaround times. With the ability to perform multiple operations in a single setup, companies can save on labor costs and minimize the risk of errors associated with multiple setups.

Additionally, multiaxis machining allows for the production of more complex parts, enabling small manufacturers to compete with larger firms. By investing in this technology, small businesses can expand their capabilities and attract a broader range of clients seeking innovative solutions.

Training and Resources for Multiaxis Machining

To effectively implement multiaxis machining, proper training and resources are essential. Numerous platforms offer courses and tutorials designed to help machinists understand the intricacies of multiaxis operations, such as Mastercam University and camInstructor. These resources provide valuable insights into software usage and best practices.

Moreover, local resellers often provide personalized training sessions, ensuring that teams are well-equipped to handle multiaxis machining. By leveraging these educational resources, businesses can enhance their workforce's skills and improve productivity in their operations.

Common Applications of Multiaxis Machining

Multiaxis machining is utilized across various industries for applications such as aerospace component manufacturing, medical device production, and automotive part fabrication. Its versatility allows for the creation of intricate parts that require precise tolerances and complex geometries.

For instance, in the aerospace sector, multiaxis machining is crucial for producing lightweight structures that meet stringent safety standards. Similarly, in the medical field, it enables the fabrication of custom implants and surgical instruments tailored to specific patient needs, showcasing the technology's adaptability and efficiency.