Part 1: Introduction

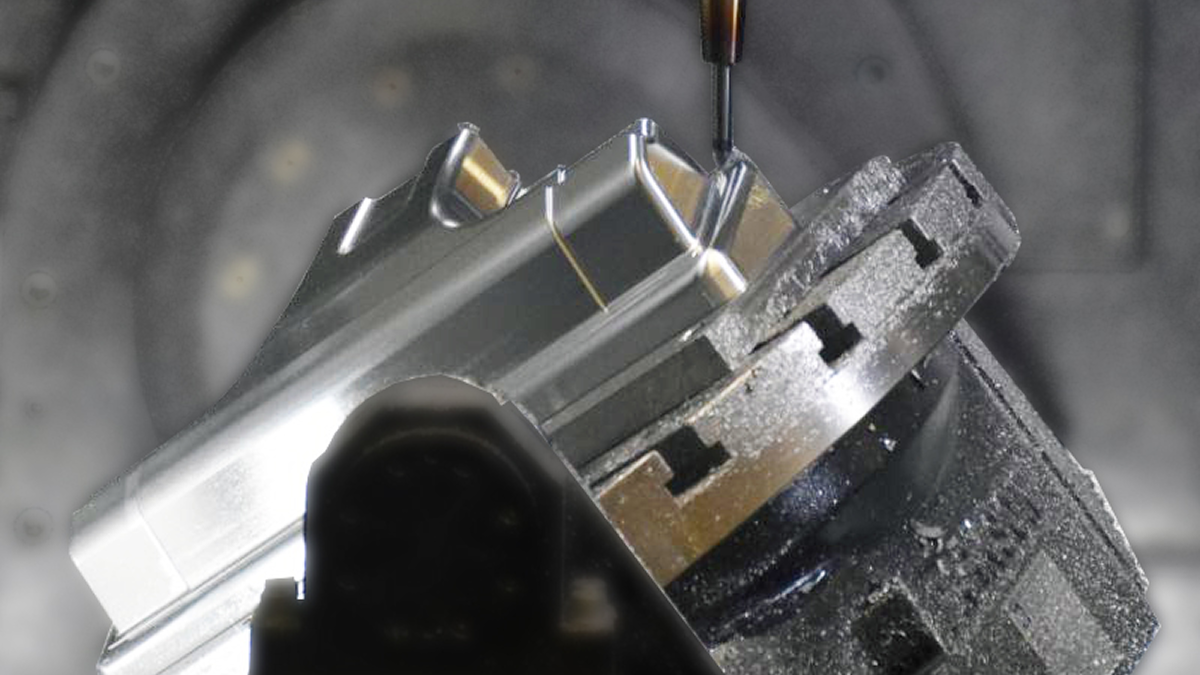

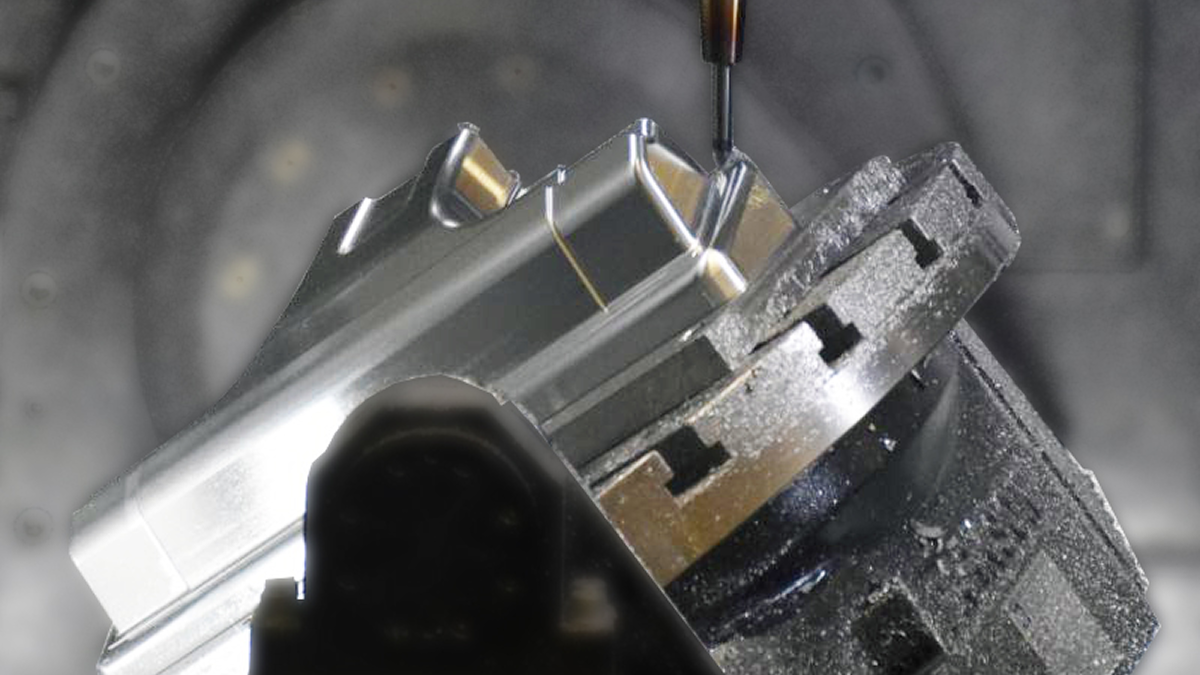

Multi-axis CNC equipment can provide significant advantages over 3-axis systems. However, to take full advantage of multi-axis you need to learn to think differently about how you set up and implement your manufacturing processes.

Part 1: WHY MULTI-AXIS?** Many manufacturers worldwide feel threatened and defensive when the subject of multi-axis is raised. They conjure up thoughts of complicated and expensive equipment with multiple spindles and axes that are way beyond their talent and financial resources to acquire and master. This is rarely the case.

Part 1: WHY MULTI-AXIS?** Many manufacturers worldwide feel threatened and defensive when the subject of multi-axis is raised. They conjure up thoughts of complicated and expensive equipment with multiple spindles and axes that are way beyond their talent and financial resources to acquire and master. This is rarely the case.

Rather than getting terrified over some fuzzy notion of how multi-axis could go wrong, a better approach to wrapping your mind around the concept is to get a better understanding of the advantages. They are clear-cut and easy to understand:

- Eliminate Setups: Every time you flip a part to machine it from a different angle you are consuming the valuable time of a skilled machinist while the machine stands idle. This results in a substantial loss of both equipment and manpower productivity. This problem is compounded when there are a large number of identical parts but can also be a factor for short runs. Stripping out set-up time, even for relatively simple parts, can result in productivity improvements of 25% to 50%…and even better for geometrically complex, precision parts.

- Improve Accuracy: Every additional flip (set-up change) introduces additional stacking errors, which can result in scrap or inconsistent manufacturing results.

- Use Manpower More Effectively: Skilled 3-axis programmers with some good guidance and training can program and operate several multi-axis systems because they don’t have to spend as much time doing meticulous setups. The additional time gained can also be used to train promising candidates to back them up.

- Open Doors for New Growth Opportunities: The ability to make difficult parts with high precision, competitive pricing and reasonable deliveries is likely to open some eyes among current and potential customers.

In short, an increasing number of users are finding out that multi-axis equipment is an important if not essential aspect of their business. While transitioning to multi-axis manufacturing is becoming increasingly important, it does not have to be overwhelmingly complex. The goal is to keep the transition process as simple as possible.

Comprehensive Machining Solutions by Axsys Incorporated

Axsys Incorporated stands at the forefront of machining technology, offering a diverse range of solutions tailored for both industrial and dental sectors. With a commitment to innovation, the company provides cutting-edge CAM software and high-performance machining centers designed to meet the evolving needs of its customers.

From advanced CAD/CAM systems to specialized dental machining equipment, Axsys ensures that its clients have access to the best tools available. The integration of technology and expertise allows for enhanced productivity and precision, making Axsys a trusted partner in the machining industry.

Training and Support for Optimal Performance

Understanding the complexities of machining technology, Axsys offers comprehensive training and support services to empower users. These resources are designed to help clients maximize the potential of their equipment and software, ensuring they can operate efficiently and effectively.

Training sessions cover a variety of topics, from basic operation to advanced techniques in CAM software. Additionally, ongoing support is available through customer service, ensuring that users can troubleshoot issues and receive expert guidance whenever needed.

Innovative Products for Dental Applications

The dental industry demands precision and reliability, and Axsys delivers with its range of specialized products. The Versamill Dental Machining Centers are engineered to provide high-quality results for dental restorations, making them a preferred choice among dental professionals.

These machining centers are designed to handle various materials, including zirconia and PMMA, allowing for versatile applications in dental practices. With a focus on user-friendly interfaces and robust performance, Axsys's dental solutions enhance workflow and patient satisfaction.

Customer-Centric E-commerce Solutions

Axsys's online store offers an extensive selection of consumable products, making it easy for customers to find what they need for their machining operations. From CAD/CAM software to raw materials, the e-commerce platform is designed to provide a seamless shopping experience.

With competitive pricing and a commitment to quality, Axsys ensures that customers can access industry-leading products without hassle. Regular promotions and updates keep users informed about the latest offerings, further enhancing the value of the online shopping experience.

Part 1: WHY MULTI-AXIS?** Many manufacturers worldwide feel threatened and defensive when the subject of multi-axis is raised. They conjure up thoughts of complicated and expensive equipment with multiple spindles and axes that are way beyond their talent and financial resources to acquire and master. This is rarely the case.

Part 1: WHY MULTI-AXIS?** Many manufacturers worldwide feel threatened and defensive when the subject of multi-axis is raised. They conjure up thoughts of complicated and expensive equipment with multiple spindles and axes that are way beyond their talent and financial resources to acquire and master. This is rarely the case.