Part 1: Introduction

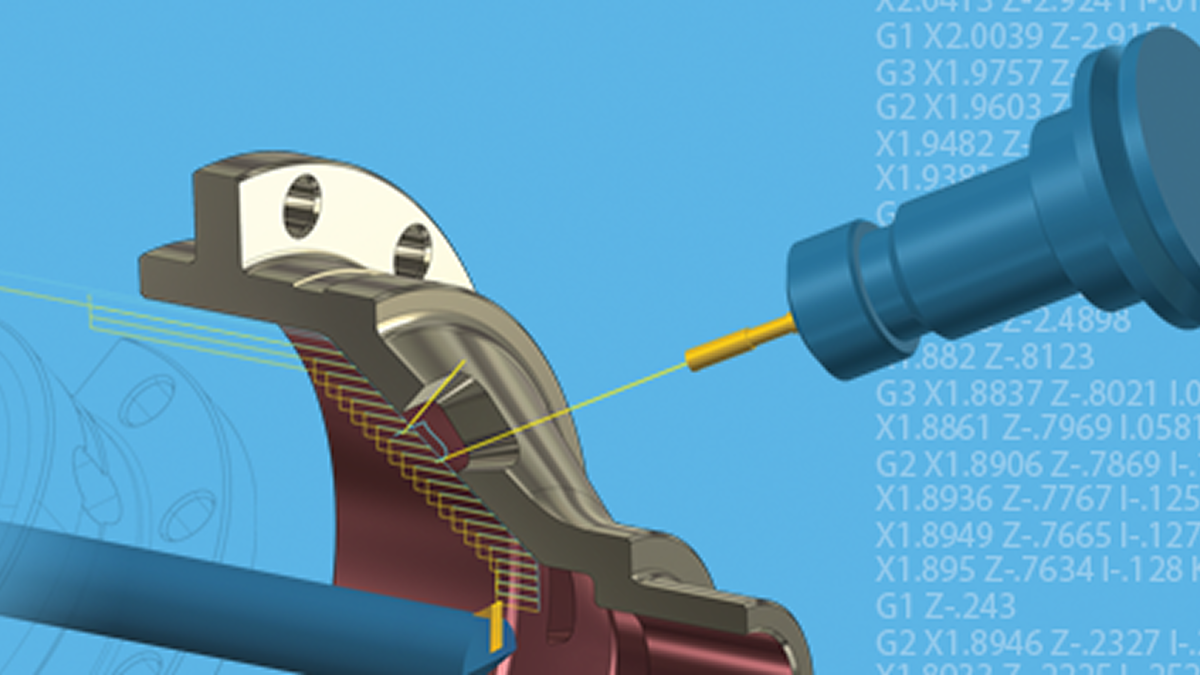

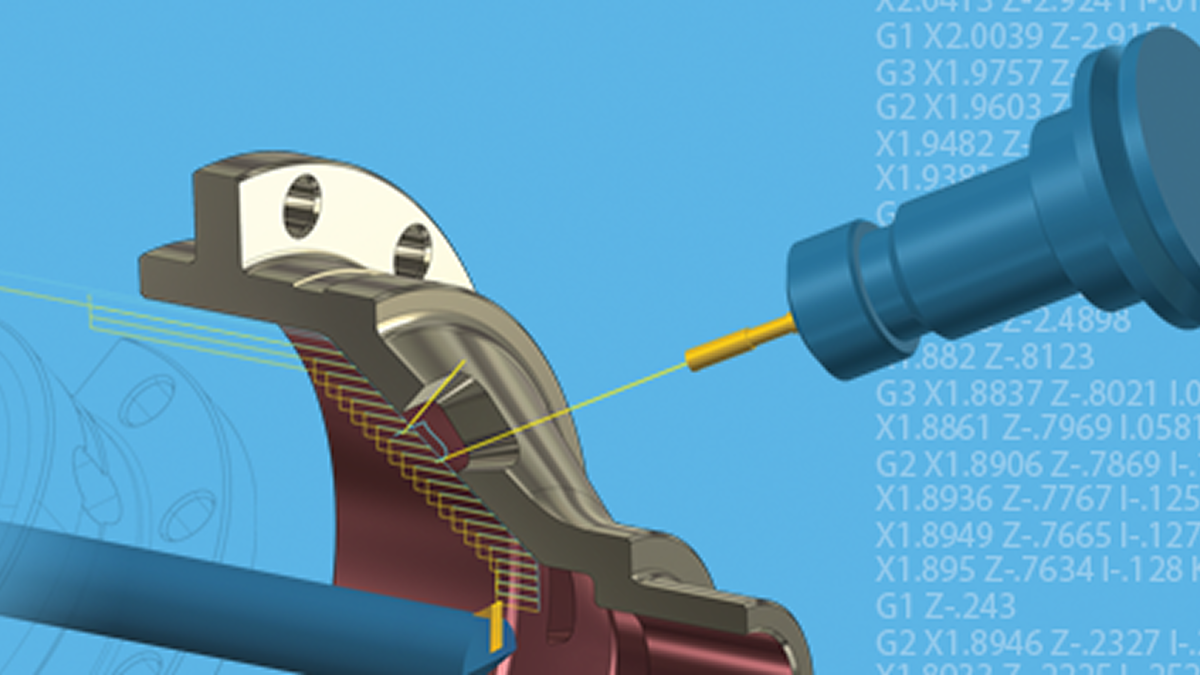

Mill-Turn CNC machines — with multiple-spindles and/or turrets— can dramatically improve machining productivity and accuracy by eliminating setups. These machines have been available for a long time. However, until recently, they were so expensive that only the largest and most sophisticated manufacturers could afford them. This is no longer the case. The makes and models of equipment in this category have grown and prices have come down. Even small job shops can now justify the cost of this equipment for making complex parts that require many operations. Manufacturers who have successfully made the transition to mill-turn manufacturing are reducing operating costs and reducing lead times for these parts, often realizing a return on investment within months.

Many other shops that wish to remain competitive in the complex part manufacturing arena are seriously considering mill-turn manufacturing but are justifiably cautious about taking this step. Mill-Turn equipment can be very complex and requires a clear and buttoned-down workflow that allows the programmer/machinist to generate safe and efficient manufacturing programs without becoming overwhelmed by the details.

Mastercam has deep experience working with customers and machine tool vendors to develop a safe and comprehensive software environment that maximizes the benefits while minimizing risks of mill-turn machining. This blog series outlines the key elements of this approach.

Education

Comprehensive Machining Solutions by Axsys Incorporated

Axsys Incorporated stands at the forefront of machining technology, offering a diverse range of solutions tailored for both industrial and dental sectors. With a commitment to innovation, the company provides cutting-edge CAM software and high-performance machining centers designed to meet the evolving needs of its customers.

From advanced CAD/CAM systems to specialized dental machining equipment, Axsys ensures that its clients have access to the best tools available. The integration of technology and expertise allows for enhanced productivity and precision, making Axsys a trusted partner in the machining industry.

Training and Support for Optimal Performance

Understanding the complexities of machining technology, Axsys offers comprehensive training and support services to empower users. These resources are designed to help clients maximize the potential of their equipment and software, ensuring they can operate efficiently and effectively.

Training sessions cover a variety of topics, from basic operation to advanced techniques in CAM software. Additionally, ongoing support is available through customer service, ensuring that users can troubleshoot issues and receive expert guidance whenever needed.

Innovative Products for Dental Applications

The dental industry demands precision and reliability, and Axsys delivers with its range of specialized products. The Versamill Dental Machining Centers are engineered to provide high-quality results for dental restorations, making them a preferred choice among dental professionals.

These machining centers are designed to handle various materials, including zirconia and PMMA, allowing for versatile applications in dental practices. With a focus on user-friendly interfaces and robust performance, Axsys's dental solutions enhance workflow and patient satisfaction.

Customer-Centric E-commerce Solutions

Axsys's online store offers an extensive selection of consumable products, making it easy for customers to find what they need for their machining operations. From CAD/CAM software to raw materials, the e-commerce platform is designed to provide a seamless shopping experience.

With competitive pricing and a commitment to quality, Axsys ensures that customers can access industry-leading products without hassle. Regular promotions and updates keep users informed about the latest offerings, further enhancing the value of the online shopping experience.